foam-made delorean car from back to the future hovers in the air using drone technology

drone technology makes foam DeLorean car fly

Designer Brian Brocken recreates the DeLorean car from the Back to the Future movies in foam and makes it hover in the air with rotating wheels. The full-scale model lifts off the ground using drone technology, and it is able to because the chassis is made of EPS foam, which is lightweight. To make it robust enough, the designer covers the foam with fiberglass sheets, which weigh around 25 grams per square meter. It protects the foam and makes it possible to paint the surface (because the paint dissolves plain EPS foam), allowing the user to also recreate the styling of the DeLorean car from the movies.

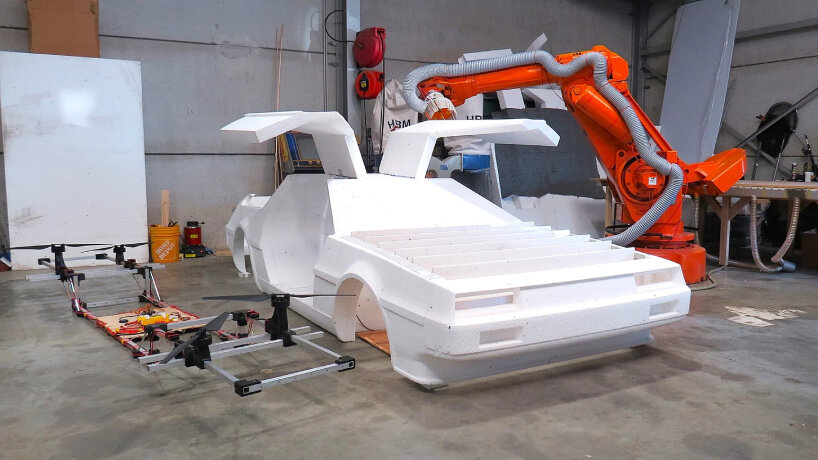

Brian Brocken designs the foam-made car’s body using the program Fusion 360, where he uses the exact measurements from the original Delorean. The 3D model is then cut into slices that could fit on a CNC machine; each slice is cut with the help of an industrial robot, which is turned into a CNC machine for the project. The car body is hollow at the front, middle, and back, and this reduces weight and allows air to pass through to the propellers when the car is in flight. The wheels rotate during flight, faithfully following the original model’s design.

all images courtesy of Brian Brocken

Recreated vehicle with original model’s gullwing door design

The foam DeLorean car takes flight using motors and propellers, similar to the ones used by drones. Before that can happen, the body needs a strong airframe, so for the first test, the designer uses an aluminum frame with 3D printed plastic parts. It isn’t strong enough, Brian Brocken concludes, because the aluminum flexes during yaw movement. He’s now developing a carbon-fiber frame, hoping to reduce the weight to about two kilos and solve the twisting issue. For the flight system, he uses four large drone motors with a 30-inch propeller. Each motor can produce about 13.5 kilograms of thrust, and so with four motors, the total thrust is about 54 kilograms.

For the foam DeLorean car to fly, air should flow to the propellers, so the designer makes the front and back of the car hollow. The hood has slats that can open and close using a flap system. Then, a linear actuator with mechanical linkages controls the flaps. When closed, the flaps cover the holes, and when open, they let air move into the propellers. This system allows the car to keep its shape while still allowing airflow. Brian Brocken also replicated the gullwing doors of the original model, its signature design element, using automatic and 3D printed door hinges hidden inside the roof and doors. So far, the designer has tested the foam DeLorean car for its maiden flight, two years after he first introduced the project and built it one part at a time.

drone technology makes foam DeLorean car fly

the chassis is made of EPS foam, which is lightweight

the designer replicates the gullwing doors of the original model

to make it robust enough, the designer covers the foam with fiberglass sheets

the designer makes the front and back of the car hollow for airflow

the designer has tested the foam DeLorean car for its maiden flight

project info:

title: First flight of the full-scale flying DeLorean

design: Brian Brocken | @bribro_12

The post foam-made delorean car from back to the future hovers in the air using drone technology appeared first on designboom | architecture & design magazine.

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0