Harry Bertoia's Diamond Chair requires "primitive method" of construction

As part of our mid-century modern series, we spotlight the iconic Diamond Chair, which artist Harry Bertoia sculpted for Hans and Florence Knoll by experimenting with metal wire. In 1950, Italian-American sculptor Bertoia was given the rare opportunity that many creatives dream about. Designers Hans and Florence Knoll granted him carte blanche to design, or sculpt, The post Harry Bertoia's Diamond Chair requires "primitive method" of construction appeared first on Dezeen.

As part of our mid-century modern series, we spotlight the iconic Diamond Chair, which artist Harry Bertoia sculpted for Hans and Florence Knoll by experimenting with metal wire.

In 1950, Italian-American sculptor Bertoia was given the rare opportunity that many creatives dream about.

Designers Hans and Florence Knoll granted him carte blanche to design, or sculpt, anything he desired. Their only requirement was that Bertoia shared anything of interest with them, with their promise that he would receive full credit for the design.

Harnessing his signature material, metal, Bertoia went on to design what came to be known as the Diamond Chair – a sculptural diamond-shaped seat formed from a lightweight wire lattice.

"I began to think in terms of what I would like as a chair," Bertoia said of the design process.

"I came into rod or wire, whether bent or straight," he continued. "I seemed to find myself at home. It was logical to make an attempt utilising the wire."

The Diamond Chair took just two years to design and enter production and has remained in production by Knoll – the eponymous company of Hans and Florence – ever since.

Today it is one of the most recognisable and iconic pieces of 20th-century furniture design.

The Diamond Chair is instantly recognisable thanks to its bent-metal form, which challenged the majority of other chair designs from the 1950s that were typically manufactured with wood.

Its frame is constructed from welded steel rods, available with either a polished chrome or black or white resin coating.

Steel was selected by Bertoia for its strength and malleability, which enabled it to be bent into shape without heat while still being able to hold a sitter.

Metal was also the sculptor's favoured material – Bertoia had begun his career developing metallic sculptures and jewellery designs.

"In sculpture, I am primarily concerned with space, form and the characteristics of metal," Bertoia said.

"In the chairs, many functional problems have to be satisfied first," he continued. "But when you get right down to it, the chairs are studies in space, form and metal too."

Alongside its different colour finishes, the Diamond Chair is available with upholstered covers that cloak its frame, or with cushions that can be attached to its concave seat with hooks.

Bertoia's goal for the Diamond Chair was for it to appear as though it is transparent and almost weightless.

"If you look at those chairs, they are mainly made of air, like sculpture," Bertoia said. "Space passes right through them."

However, achieving this airiness was no mean feat, with Bertoia himself describing the chair's production as "a fairly complex system".

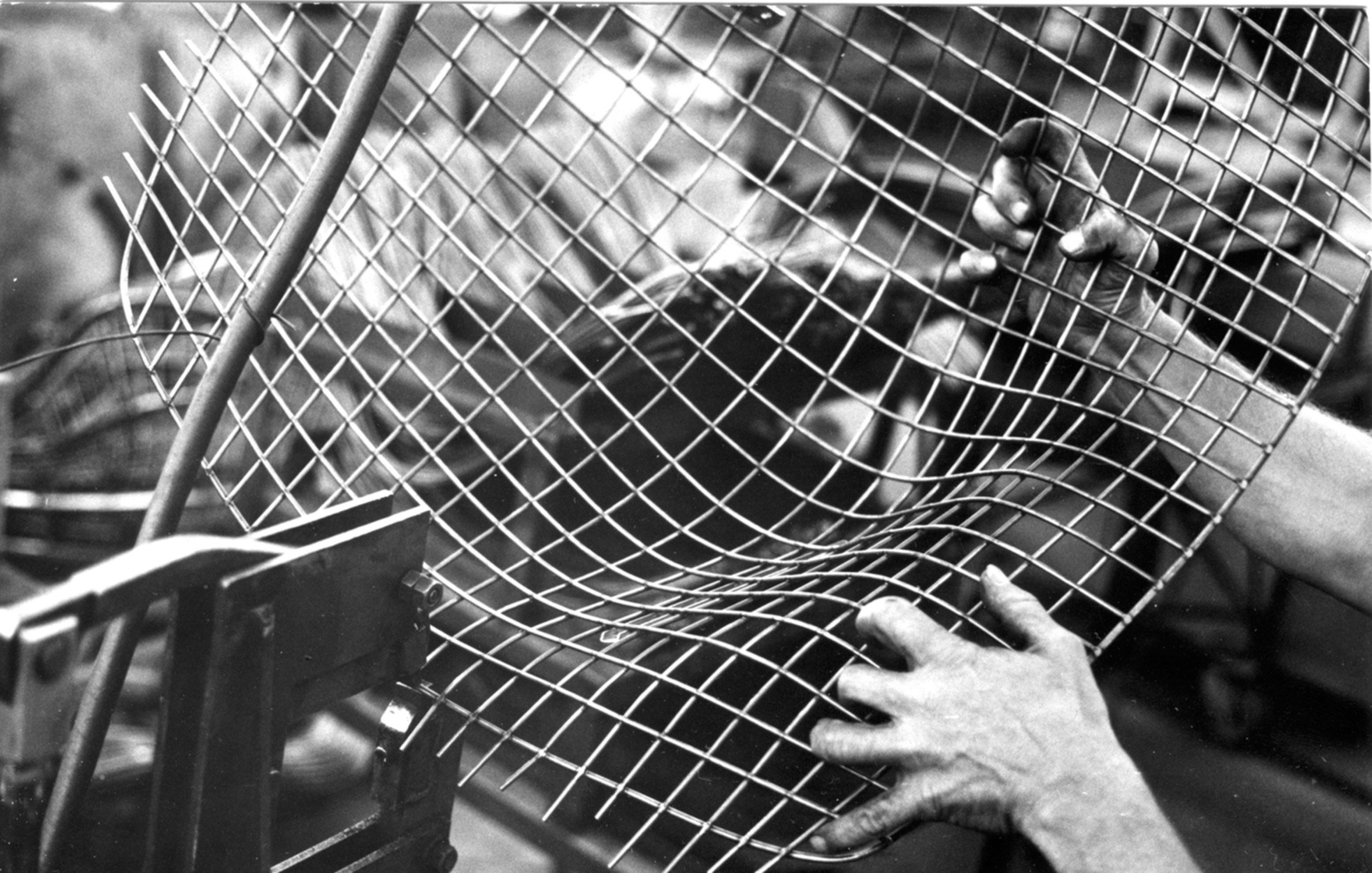

The system was developed through experimentation, with Bertoia hand-bending the wires to the desired curves himself. Later, he developed moulds and jigs with Knoll associates Don Petitt and Bob Savage to help streamline the process.

After the wires were cut and bent, the chair was braced together using a power drill and its joints were hammered together.

The team's goal was originally to develop a way to carry out this process using machinery, though this was never achieved. And so, more than half a century later, the Diamond Chair is still manufactured using the same processes developed by Bertoia with Petitt and Savage.

"By curving the wires, a very primitive method was found, but the intent was to see if a machine could do it," Bertoia said.

"Some research was done in trying to find out if there were machines that could bend the wire," he continued. "They could make a straight wire and weld it or bend it sharp and weld it, but no curves."

While this sounds laborious, Bertoia's preferred method was working by hand.

"When you really have something in front of you that can really physically be held, it becomes quite easier to make adjustments," he explained.

It is no surprise that the same process is also used for other furniture pieces designed by Bertoia for Knoll, including the wireframe bar stool, asymmetric chaise and side chairs that form part of the Bertoia collection.

There is also an 18 karat gold-plated version of the Diamond Chair, made by Knoll in 2015 to celebrate the sculptor's 100th birthday.

Bertoia's first design for the company was an outdoor bench, which does not use a wire lattice but does feature a welded metal base. Knoll said this represents his earliest explorations of the system that came to be used for the Diamond Chair.

"Hans and Florence never demanded that Bertoia design furniture, but instead encouraged him to explore whatever he liked," Knoll said.

"Needless to say, Harry Bertoia arrived at something outstanding. His iconic wire furniture collection, introduced in 1952, is recognized worldwide as one of the great achievements of 20th-century furniture design."

The images are courtesy of Knoll.

Mid-century modern

This article is part of Dezeen's mid-century modern design series, which looks at the enduring presence of mid-century modern design, profiles its most iconic architects and designers, and explores how the style is developing in the 21st century.

This series was created in partnership with Made – a UK furniture retailer that aims to bring aspirational design at affordable prices, with a goal to make every home as original as the people inside it. Elevate the everyday with collections that are made to last, available to shop now at made.com.

The post Harry Bertoia's Diamond Chair requires "primitive method" of construction appeared first on Dezeen.

What's Your Reaction?

.jpg?#)